Culture Paper Making Line

100TD Fourdrinier Culture Paper Machine

The 100TD Fourdrinier Culture Paper Machine is named after the Fourdrinier process, a traditional method of papermaking that involves forming a continuous sheet of paper on a moving wire mesh. Whether it’s adjusting the paper width, thickness, or speed, the machine can be tailored to suit various production requirements.

Read more

High-Quality Doctor Blade for Paper Production

In the world of paper manufacturing, precision and efficiency are paramount. Every component of a paper machine plays a crucial role in ensuring the final product meets the highest standards of quality. The Doctor Blade aids in the efficient removal of water, speeding up the drying process and improving the overall efficiency of the paper machine.

Read more

High-Performance Felt for Paper Machine

The felt’s primary function is to support the paper web as it moves through the machine, ensuring smooth operation, consistent moisture removal, and uniform paper quality. Leizhan is a leading innovator in the paper machinery industry, has introduced a new line of high-performance felts designed to optimize paper production processes.

Read more

Enhance Paper Production with Calender

Calender is a series of rolls used in the final stages of paper production to smooth and compact the paper sheet, enhancing its surface finish and controlling thickness. Leizhan’s calender utilizes state-of-the-art rolling technology that provides uniform pressure across the entire width of the paper.

Read more

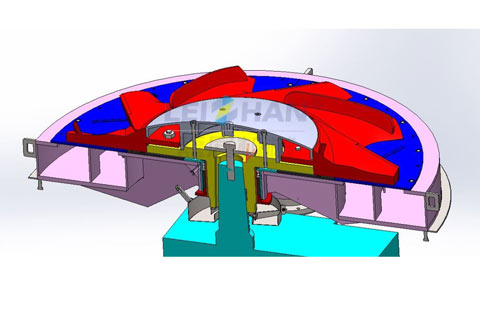

D-Type Hydrapulper for Paper Production

The D-type hydrapulper is a vital component in the pulp production line, primarily used for the initial pulp processing stage in paper mills. With its superior mixing capability, Leizhan’s D-type hydrapulper ensures the production of high-quality pulp.

Read more

Cultural Copy Paper Making Machine

Cultural copy paper is a high-quality paper used primarily for printing and copying purposes, often characterized by its smooth texture and superior whiteness. Designed for large-scale production, Leizhan’s cultural copy paper machines are capable of handling high volumes of pulp, leading to increased productivity.

Read more

High-Speed Stock Washer for Pulping Process

The high-speed stock washer is an essential component in the pulping process, particularly for recycled paper processing. Leveraging advanced technology, the high-speed stock washer operates at unmatched speeds, increasing throughput and reducing processing time.

Read more

A4 Cultural Paper Production Machine

Leizhan has established itself as a leader in the industry, providing innovative solutions for paper production. One of their standout offerings is the A4 cultural paper production machine, designed specifically to meet the demanding needs of paper plants looking to produce high-quality A4 paper efficiently.

Read more