Kraft Paper Making Line

Pulp Dilution In Paper Pulping Process

In paper pulping process, pulp dilution is necessary due to high concentration pulp in pulp chest pool. But there are some factors influencing pulp concentration after pulp dilution.

Read more

Heavy Impurity Cleaner Equipment

Heavy Impurity Cleaner is the pulp cleaner equipment for removing heavy impurities like gravel, scrap iron, dust and large ink particles from different kind of pulp.

Read more

Paper Machine Forming Wire Section

Paper machine forming section is important part for wet paper sheet forming in paper making process, there are some tips about paper machine forming wire maintenance.

Read more

Paper Sizing Machine In Paper Making Line

Paper Sizing Machine is for coating a layer sizing on paper sheet surface to improve the paper strength in paper making process, the surface sizing is the most common method for sizing.

Read more

Reeling Machine For Paper Making

Paper reeling machine is used in the end of paper machine for the finished paper reeling, there are different types paper reeling machine for different requirement.

Read more

50T/D Kraft Paper Making Project

Paper machine is the most essential in paper making process. For 50T/D Kraft Paper Making Project, is adopt the 2400mm paper machine for kraft paper making.

Read more

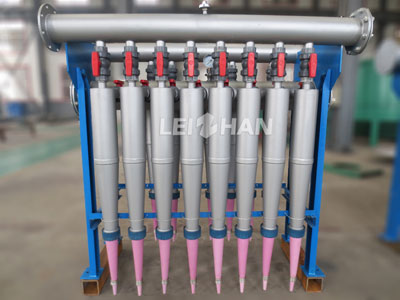

Low Density Cleaner For Pulp Cleaning

In paper pulping process, low density cleaner is the pulp cleaning equipment for removing heavy impurities in the pulp, like gravel, scrap iron, dust and large ink particles.

Read more

Disc Thickener VS Cylinder Thickener

Disc Thickener and Cylinder Thickener both are pulp thickener equipment for pulp washing and thickening, but they have different using in paper pulping process.

Read morePage Links: First PagePrevious3334353637383940414243NextLast Page